Dịka nnyocha na nyocha si kwuo, nchara bụ otu n'ime ihe ndị dị mkpa na-emebi valvụ urukurubụba. Ebe ọ bụ na oghere dị n'ime na-emetụ ihe ahụ aka, ọ na-emebi nke ukwuu. Mgbe nchara gasịrị, dayameta valvụ ahụ na-adị obere ma iguzogide mmiri na-abawanye, nke na-emetụta nnyefe nke ihe ahụ.elu nke ahụ valvụ ahụA na-etinyekarị ya n'ala ma ọ bụ n'okpuru ala. Elu ya na-emetụ ikuku aka, ikuku ahụ na-adịkwa mmiri mmiri, ya mere ọ na-adịkarị nchara nchara. A na-ekpuchi oche valvụ ahụ kpamkpam ebe oghere dị n'ime ya na-emetụ ihe ahụ aka. Ya mere, ọgwụgwọ mkpuchi elu nke ahụ valvụ na efere valvụ bụ ụzọ nchekwa kachasị dị ọnụ ala megide nchara na gburugburu ebe obibi.

1. Ọrụ nke mkpuchi elu nke valvụ urukurubụba

01. Nchọpụta ihe ahụ valvụ

A na-etinye agba oyi akwa elu ahụ n'elu ihe ndị a na-anaghị eji arụ ọrụ nke ahụ valvụ na bonnet. Site na akara agba a, anyị nwere ike ịchọpụta ngwa ngwa ihe dị na ahụ valvụ ahụ ma ghọta nke ọma njirimara ya.

| Ihe ahụ valvụ valvụ | Agba Agba | Ihe ahụ valvụ valvụ | Agba Agba |

| Ígwè a kpụpụtara | Ojii | Ígwè Ductile | Anụ anụnụ anụnụ |

| Ígwè e ji akpụpụta | Ojii | WCB | Isi awọ |

02. Mmetụta nchekwa

Mgbe e ji agba kpuchie elu ahụ valvụ ahụ, elu ahụ valvụ na-adị iche na gburugburu ebe obibi. A pụrụ ịkpọ mmetụta nchebe a mmetụta nchebe. Agbanyeghị, a ghaghị ịkọwa na obere agba enweghị ike inye mmetụta nchebe zuru oke. N'ihi na polima nwere oke ikuku iku ume, mgbe mkpuchi ahụ dị obere, oghere nhazi na-ekwe ka mmiri na molekul oxygen na-agafe n'enweghị nsogbu. Valvụ mkpuchi dị nro nwere ihe achọrọ siri ike na ọkpụrụkpụ nke mkpuchi epoxy resin n'elu. Iji melite enweghị ike ịbanye na mkpuchi ahụ, mkpuchi mgbochi ire ere kwesịrị iji ihe ndị na-emepụta fim nwere obere ikuku na ihe ndị na-ejupụta siri ike nwere ihe nchebe dị elu. N'otu oge ahụ, a ga-amụba ọnụọgụ nke mkpuchi ka mkpuchi ahụ wee ruo ọkpụrụkpụ ụfọdụ ma dị oke ma na-enweghị oghere.

03. Mgbochi nrụrụ aka

Ihe ndị dị n'ime agba ahụ na-emeghachi omume na ígwè ahụ iji mee ka elu ígwè ahụ dịgide ma ọ bụ mepụta ihe nchebe iji melite mmetụta nchebe nke mkpuchi ahụ. Maka valvụ nwere ihe pụrụ iche achọrọ, ị ga-elebara ihe mejupụtara agba ahụ anya iji zere mmetụta ọjọọ dị njọ. Na mgbakwunye, valvụ ígwè a kpụrụ akpụ nke ejiri na paịpụ mmanụ nwekwara ike ịrụ ọrụ dị ka ihe mgbochi nchara organic n'ihi ngwaahịa mmebi nke ụfọdụ mmanụ na ihe ncha ígwè na-akpọnwụ.

04. Nchedo elektrọnik

Mgbe mkpuchi dielectric na-abanye n'ime ahụ batara n'elu ígwè ahụ, nchara electrochemical dị n'okpuru ihe nkiri ahụ ga-etolite. A na-eji ígwè nwere ọrụ dị elu karịa ígwè eme ihe dị ka ihe e ji eme ihe mkpuchi, dị ka zinc. Ọ ga-arụ ọrụ nchebe dị ka anode àjà, ihe ndị na-emebi emebi nke zinc bụ zinc chloride na zinc carbonate nke e ji nnu mee, nke ga-ejupụta oghere dị na ihe nkiri ahụ ma mee ka ihe nkiri ahụ sie ike, na-ebelata nchara nke ukwuu ma na-agbatị ndụ ọrụ nke valvụ ahụ.

2. Mkpuchi a na-ejikarị na valvụ ígwè

Ụzọ ọgwụgwọ elu nke valvụ gụnyere mkpuchi agba, galvanizing na mkpuchi ntụ ntụ. Oge nchekwa nke agba dị mkpụmkpụ ma enweghị ike iji ya n'ọnọdụ ọrụ ruo ogologo oge. A na-ejikarị usoro galvanizing eme ihe na pipelines. A na-eji galvanizing ọkụ na electro-galvanizing. Usoro a dị mgbagwoju anya. Ọgwụgwọ tupu oge eruo na-eji usoro pickling na phosphating. A ga-enwe ihe fọdụrụ na acid na alkali n'elu ọrụ ahụ, na-ahapụ nchara. Ihe egwu zoro ezo na-eme ka oyi akwa galvanized dị mfe ịda. Nguzogide nchara nke ígwè galvanized bụ afọ 3 ruo 5. Mkpuchi ntụ ntụ eji na valvụ Zhongfa anyị nwere njirimara nke mkpuchi dị arọ, iguzogide nchara, iguzogide mbuze, wdg, nke nwere ike imezu ihe achọrọ nke valvụ n'okpuru ọnọdụ ojiji nke sistemụ mmiri.

01. Mkpuchi resin epoxy nke ahụ valvụ

Nwere njirimara ndị a:

·Nguzogide ire ere: Ogwe ígwè e ji epoxy resin kpuchie nwere ezigbo iguzogide ire ere, ike njikọ ya na simenti na-ebelata nke ukwuu. Ha dabara adaba maka ọnọdụ ụlọ ọrụ mmepụta ihe na gburugburu ebe mmiri dị ma ọ bụ ihe mgbochi ire ere.

·Njikọ siri ike: Ọdịdị nke otu polar hydroxyl na njikọ ether dị n'ime usoro molekul nke epoxy resin na-eme ka ọ na-arapara nke ọma na ihe dị iche iche. Mbelata nke epoxy resin mgbe a gwọrọ ya dị obere, nrụgide dị n'ime ya dị obere, mkpuchi elu nchebe adịghịkwa mfe ịda ma daa.

· Njirimara eletriki: Sistemụ resin epoxy a gwọrọ agwọ bụ ihe mkpuchi dị mma nke nwere nnukwu ihe onwunwe dielectric, iguzogide ntapu elu, na iguzogide arc.

·Ihe Na-eguzogide Ebu: Sistemụ resin epoxy a gwọrọ agwọ na-eguzogide ọtụtụ ebu ma enwere ike iji ya mee ihe n'ọnọdụ okpomọkụ siri ike.

02. Ihe e ji efere naịlọn mee nke nwere valvụ

Mpempe akwụkwọ naịlọn na-eguzogide nchara nke ukwuu, a na-ejikwa ha nke ọma n'ọtụtụ ụzọ dịka mmiri, apịtị, nri na mmiri mmiri.

·Arụmọrụ n'èzí: Mkpuchi efere naịlọn nwere ike ịgafe ule ịgba nnu. Ọ gbapụbeghị mgbe e mikpuru ya n'ime mmiri oké osimiri ihe karịrị afọ 25, yabụ enweghị mmebi na akụkụ ígwè.

·Iguzogide iyi: Nguzogide iyi dị mma nke ukwuu.

·Nguzogide mmetụta: Enweghị ihe ịrịba ama nke ịpụpụ n'okpuru mmetụta siri ike.

3. Usoro ịgba mmiri

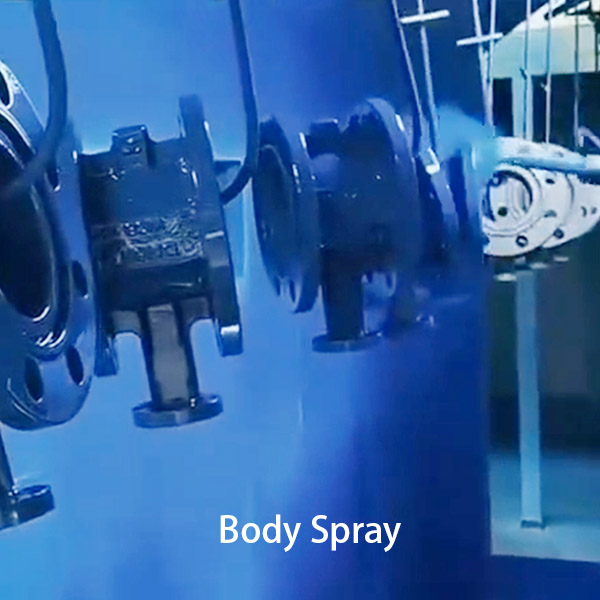

Usoro ịgbasa ihe a bụ ọgwụgwọ tupu workpiece → iwepụ uzuzu → ikpo ọkụ tupu → ịgbasa (praịmarị - ịkpụcha - mkpuchi elu) → ịgbasa → oyi.

Ịgbasa Ngwa ịgbasa na-ejikarị ịgbasa electrostatic. Dịka nha nke ngwa ọrụ si dị, enwere ike kewaa ịgbasa electrostatic n'ime ahịrị mmepụta ịgbasa electrostatic ntụ ntụ na otu ịgbasa electrostatic ntụ ntụ. Usoro abụọ ahụ bụ otu, isi ihe dị iche bụ ụzọ ntụgharị nke ngwa ọrụ ahụ. Ahịrị mmepụta ịgbasa na-eji agbụ nnyefe maka nnyefe akpaka, ebe a na-ebuli ngwa ịgbasa aka. A na-achịkwa ọkpụrụkpụ nke mkpuchi ahụ na 250-300. Ọ bụrụ na ọkpụrụkpụ ya erughị 150 μm, arụmọrụ nchebe ga-ebelata. Ọ bụrụ na ọkpụrụkpụ ya karịrị 500 μm, njikọta mkpuchi ahụ ga-ebelata, iguzogide mmetụta ga-ebelata, oriri ntụ ahụ ga-abawanye.